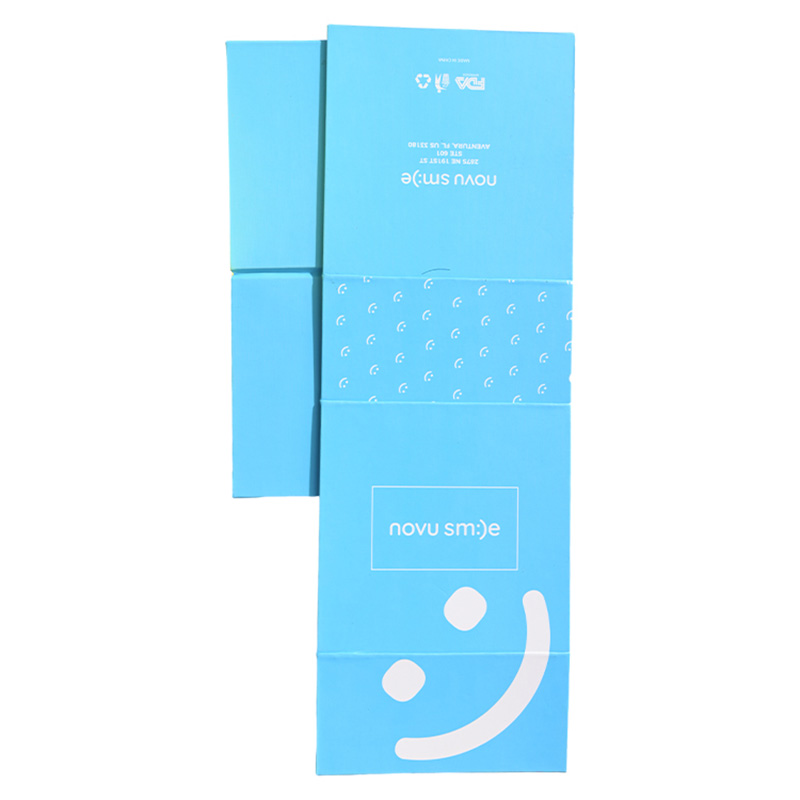

Custom Wholesale Foldable Rigid Boxes for Electronics

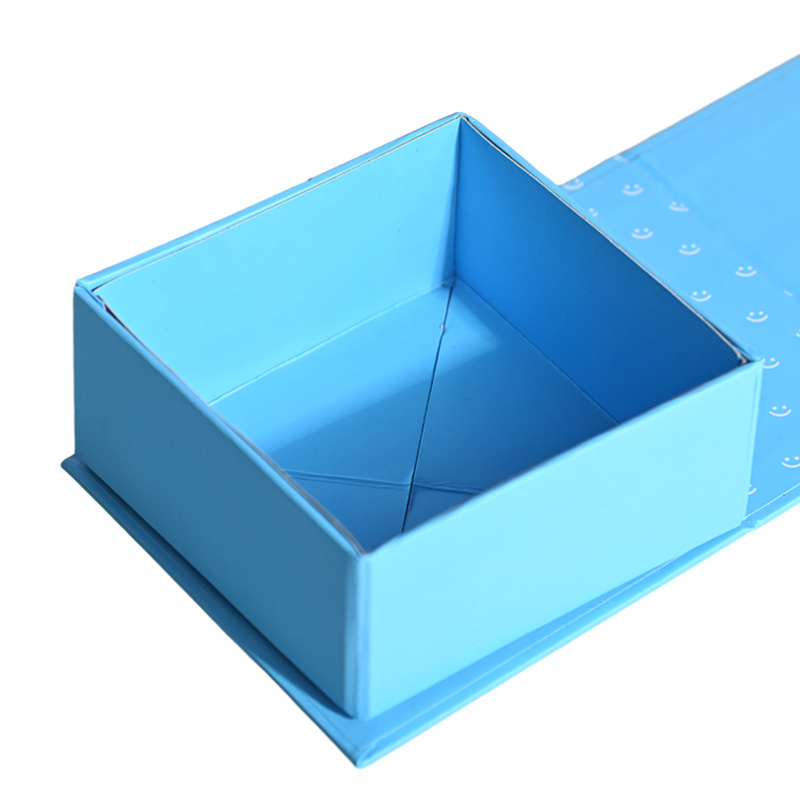

These premium folding rigid boxes are ideal for showcasing and safeguarding your electronic goods. Our bespoke wholesale foldable rigid boxes for electronics are made to blend strength, style, and practicality. They have exceptional structural strength while retaining a lightweight, space-saving foldable shape because they are made of strong, stiff cardboard with a smooth laminated surface. While the colorful custom printing improves your brand's image and gives customers an unforgettable unpacking experience, the magnetic closure guarantees safe storage.

Quick Quote

Specifications

| Product Info | Box Shape | Printing | Material | Treatment |

| Foldable Rigid Box | 4 Colors | Artpaper + GreyBoard | Matte Lamination | |

| Custom | MOQ | Incoterms | Payment Terms | Delivery Reference (By Sea) |

| 500 Pieces | EXW | 30% deposit and balance against shipping document | North America: 3-4 weeks Europe: 3-4 weeks South America: 4-5 weeks Asia: 1-2 weeks |

Description

Product Features

- Durable & Premium Materials: Made from sturdy greyboard and coated with high-quality art paper for a refined surface and long-lasting protection.

- Foldable Structure: Smart collapsible design saves storage space and shipping costs while maintaining rigidity and strength.

- Secure Magnetic Closure: Keeps electronics and accessories safe during handling and transport.

- Fully Customizable: Adjustable size, color, printing, and finishing to match your brand identity or product theme.

- Eco-Friendly Manufacturing: Produced using sustainable processes and recyclable materials for an environmentally responsible choice.

- Enhances Customer Experience: Stylish design and premium feel elevate the unboxing moment, increasing perceived product value.

Foldable rigid boxes are gaining popularity as e-commerce expands, since brands can deliver a premium unboxing experience while keeping logistics cost in check. Sustainability is another driver, as the foldable design can reduce carbon footprint through optimized transportation.

From the initial idea to the final product, Brothersbox can offer you comprehensive packaging solutions.

At Brothersbox, we understand the journey from a mere concept to a tangible product. Our team of experts utilizes cutting-edge technology and innovative design to craft packaging that not only protects but also enhances your product's appeal. Whether it's custom shapes, sustainable materials, or unique finishes, we've got you covered with our all-encompassing packaging solutions.

View More

View More

How It Works

Start customizing your gift boxes in just 8 steps!

FAQ

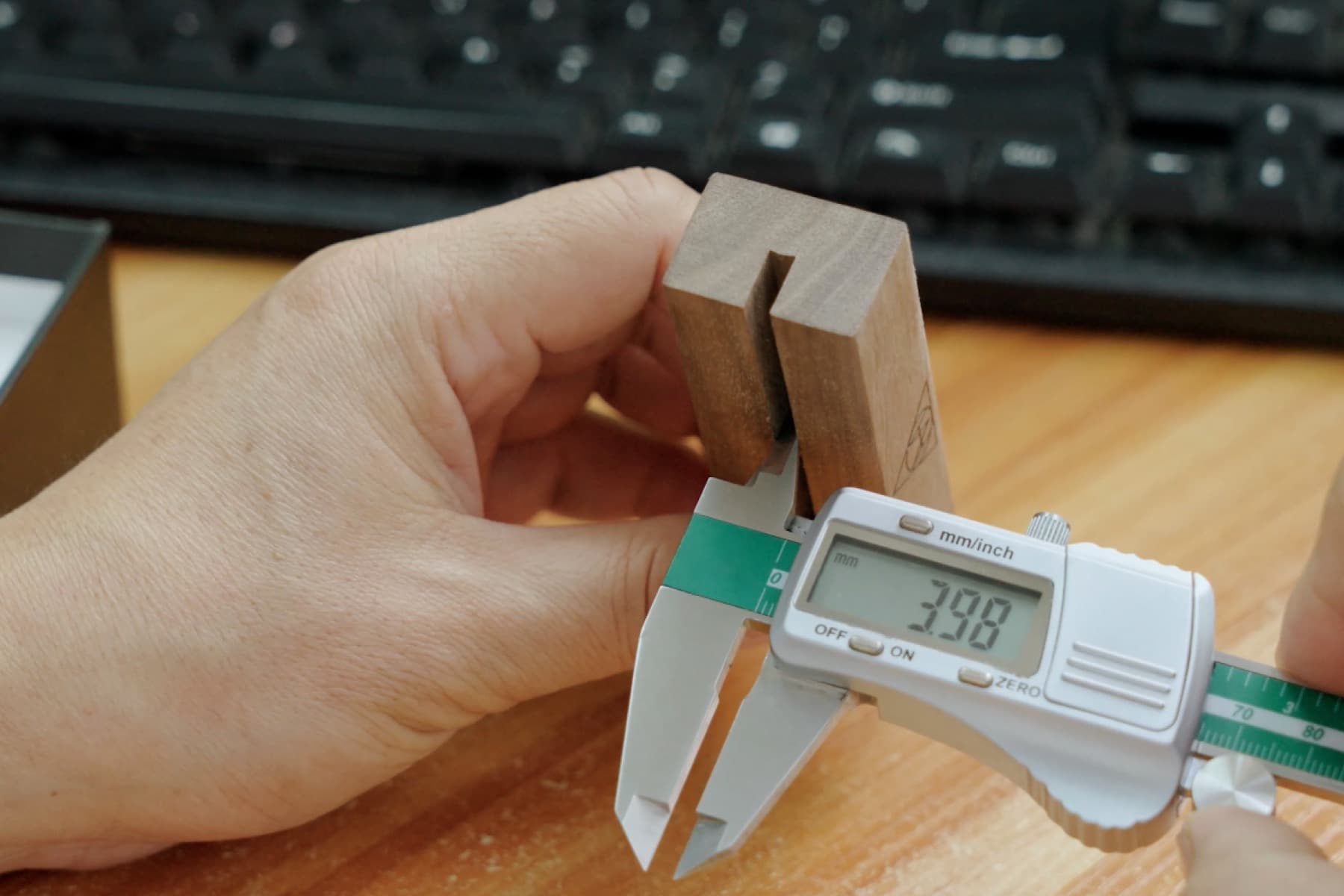

I want to customize the packaging for the product, but I don't know the appropriate packaging size, could you give me some recommendations?

What is your MOQ?

I dont need the custom product, just send me the existing product.

Can customize my own brand?

How long does it take to make sample?

More Products

Newsletter

Address

:

No.29 Jinfu 2nd Road, Huanan Ind Park, Liaobu City, Dongguan City, Guangdong Province, China

Office Address

:

No.6

Zhuangyuan Road, Park Songshan Lake, Dongguan City, Guangdong Province, China, 523808

Copyright©Brothersbox Industrial Co., Ltd. All rights reserved. |

Sitemap